Our Industry

Our Service

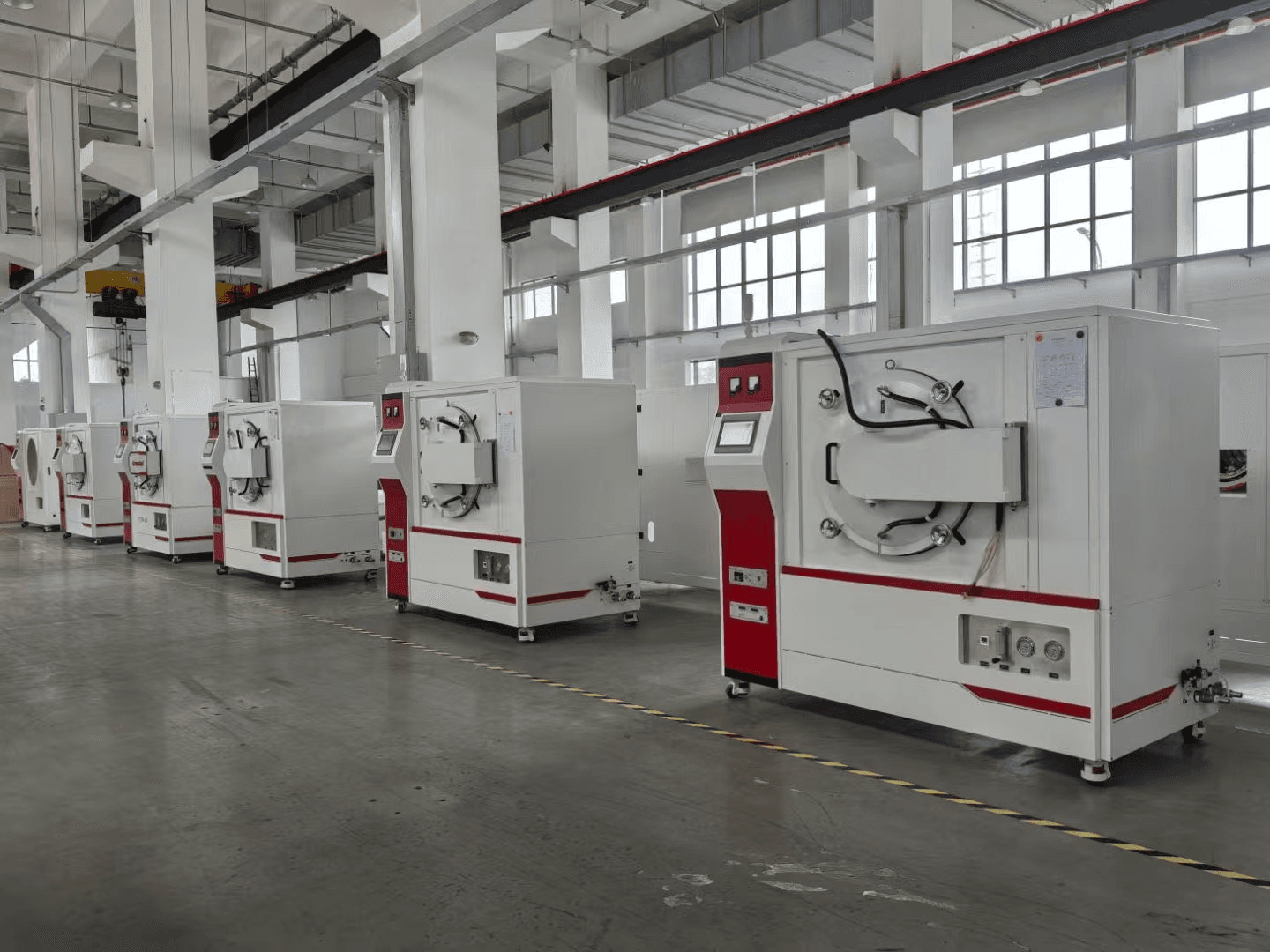

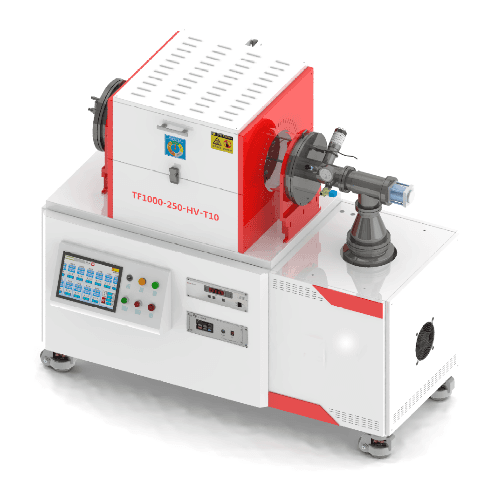

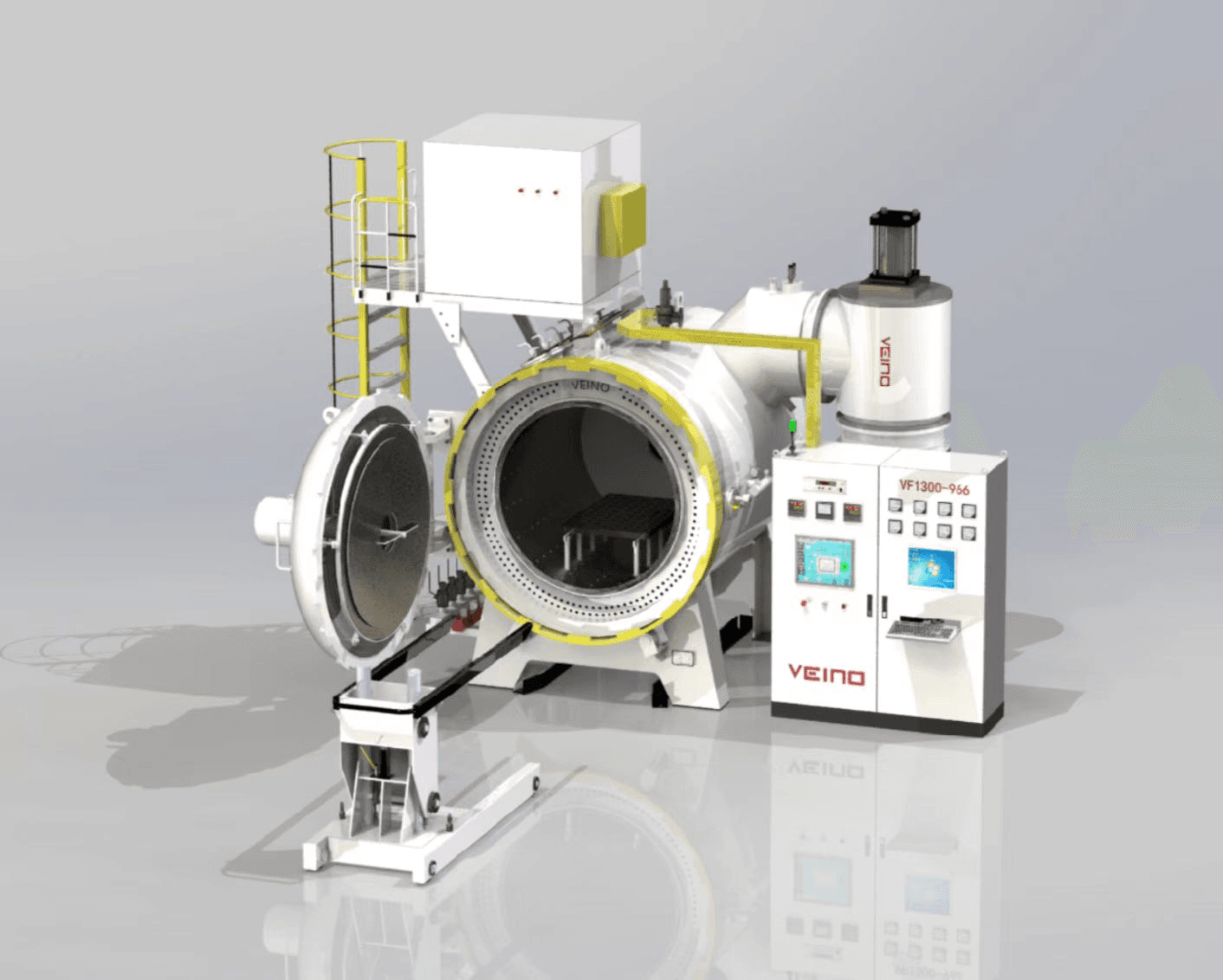

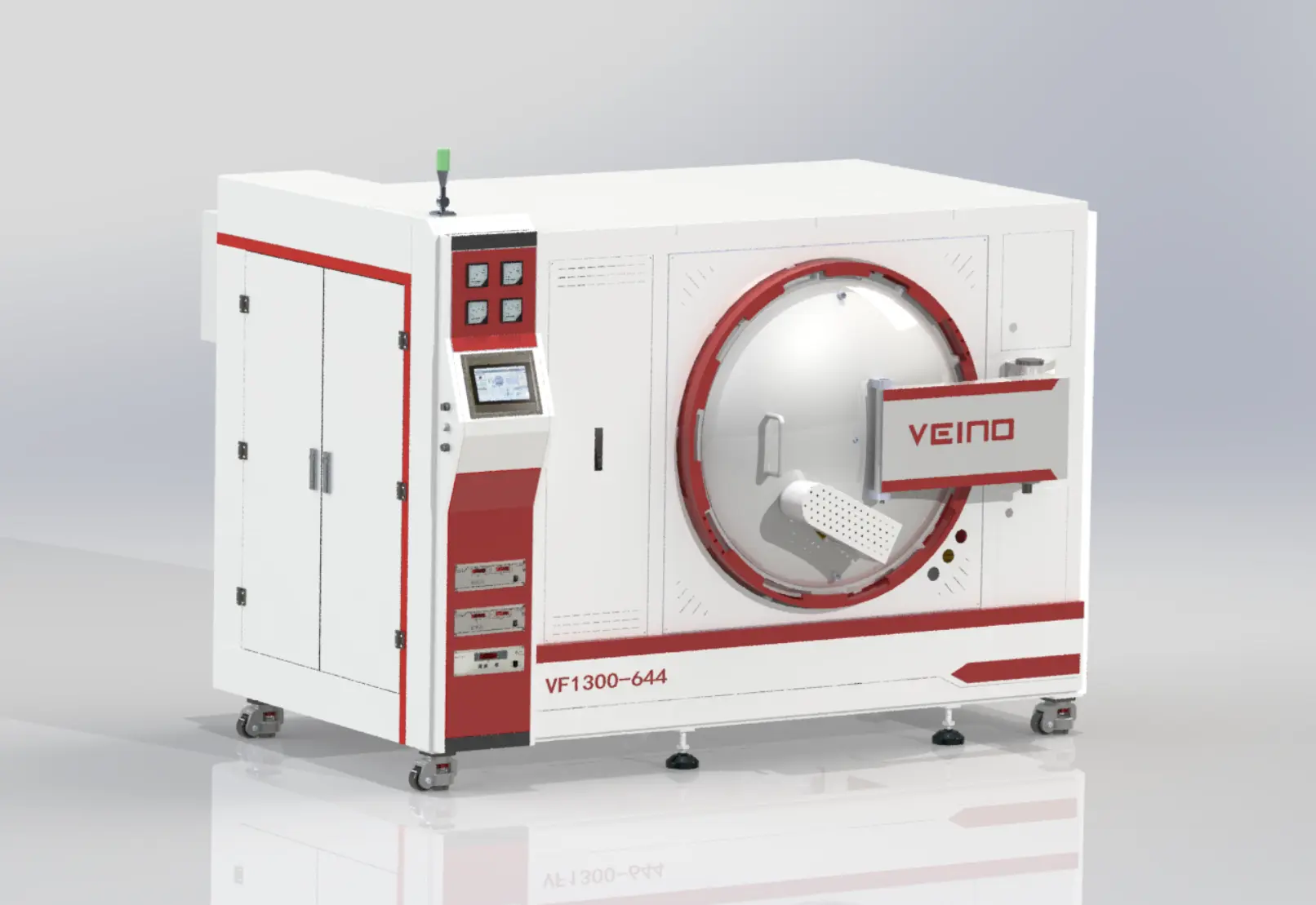

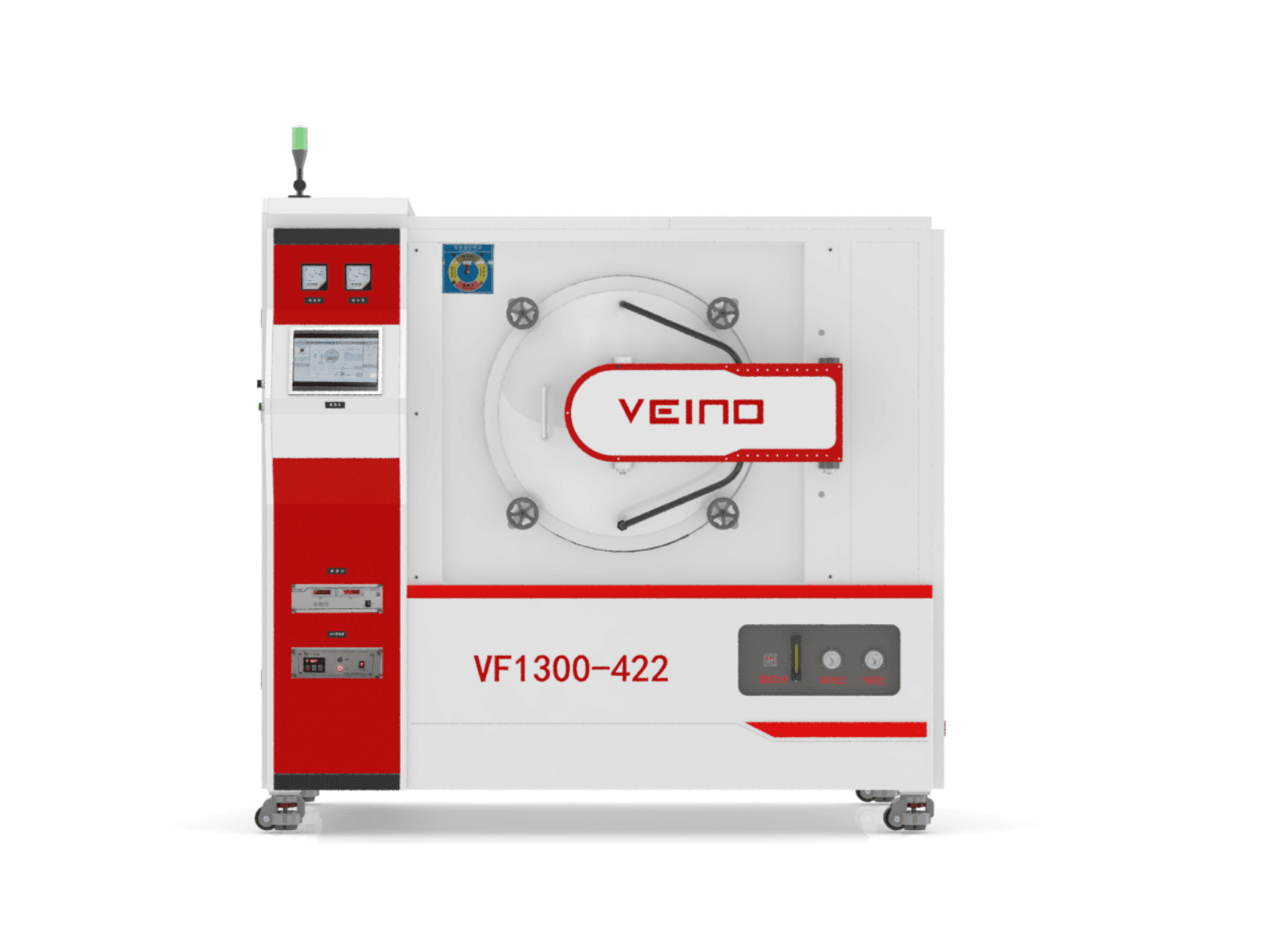

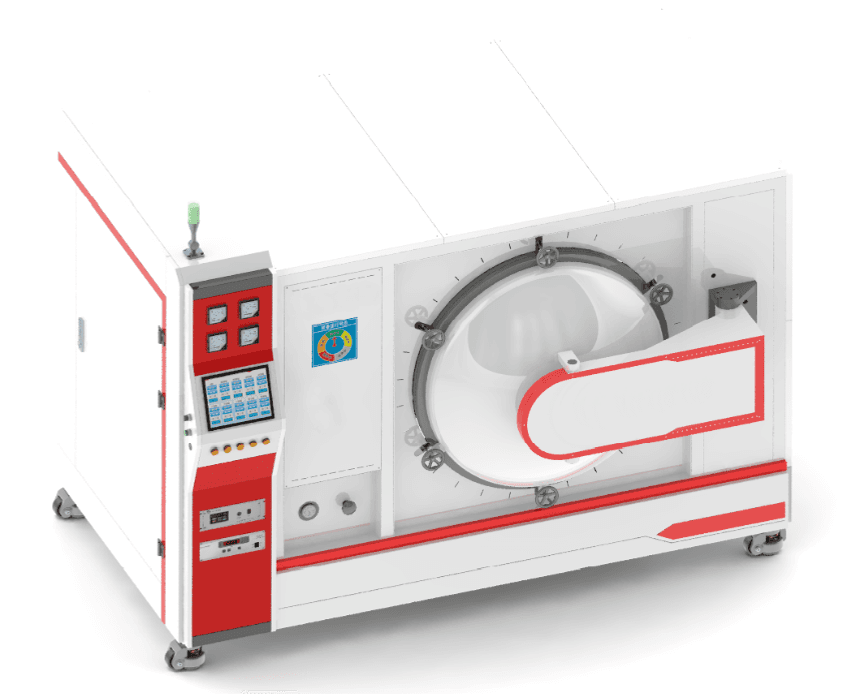

Industrial Furnace Manufacturing

We design and supply advanced vacuum furnaces for industrial production, research labs, and universities.

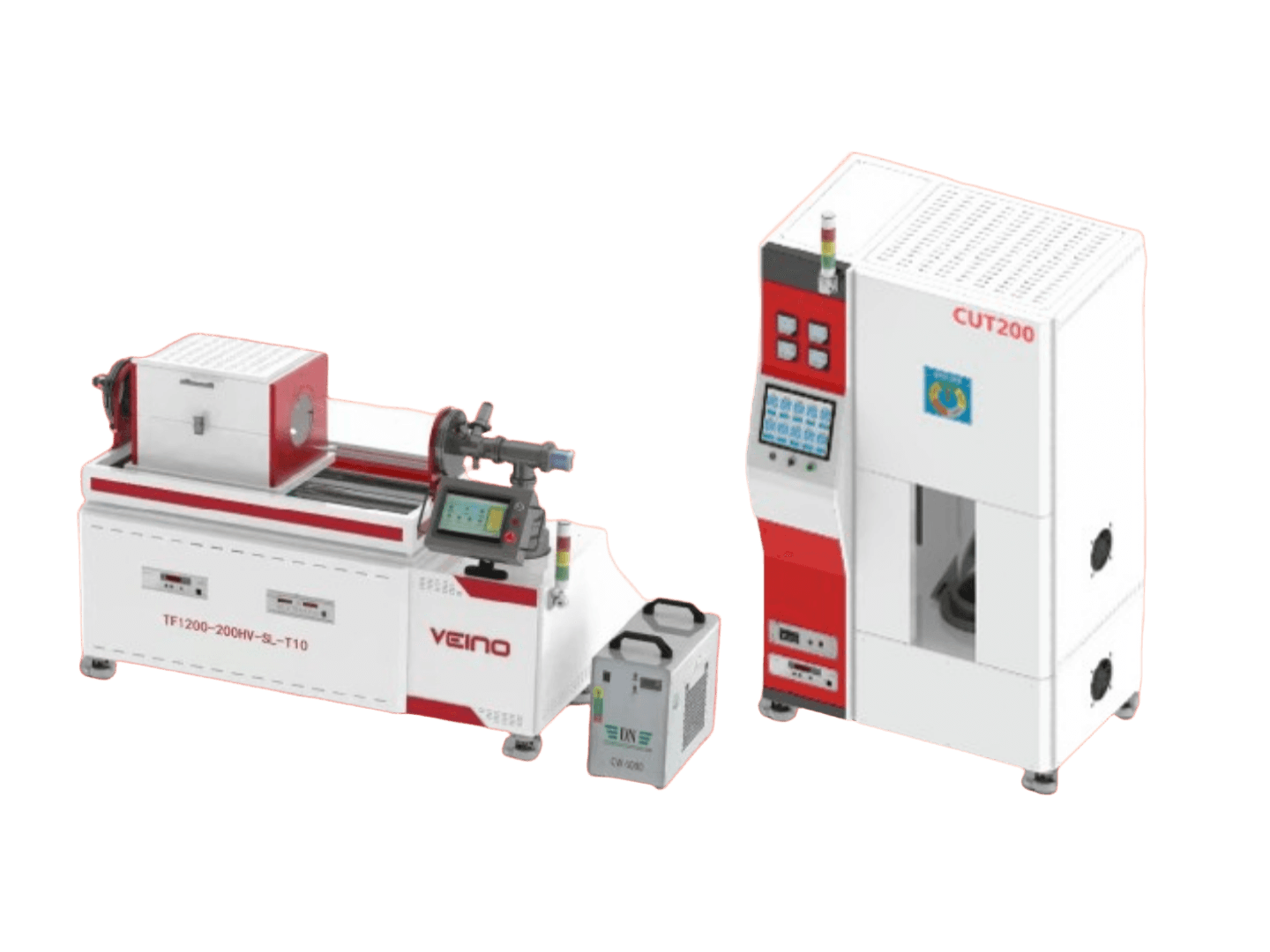

Process Verification & Optimization

Our experts help optimize heat treatment processes for efficiency, quality, and compliance.

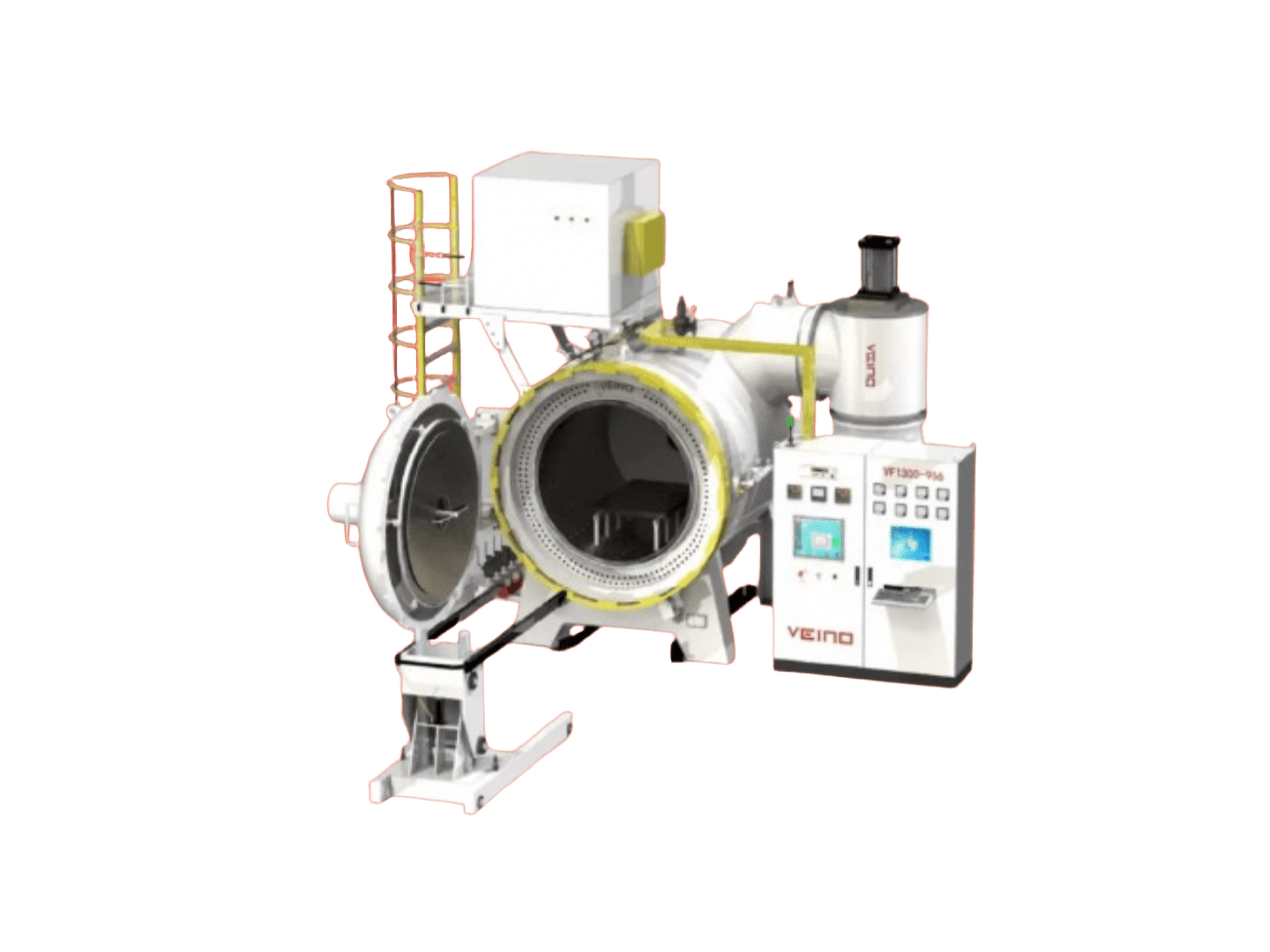

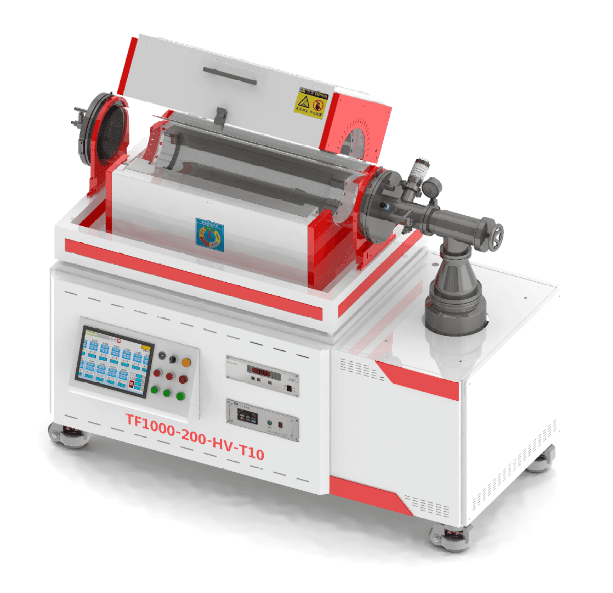

Vacuum Heat Treatment Solutions

We deliver advanced vacuum heat treatment solutions for precision, durability, and performance.

Training & After-Sales Support

We provide expert training and reliable after-sales service to ensure long-term equipment efficiency.

Featured Blogs

Industry News

November 23, 2024

Normanthan Broadens Its Impact Across Key High-Tech Industries

Industry News

November 23, 2024

Normanthan Unveils Next-Generation Multi-Functional Vacuum Furnaces

Product News

November 23, 2024

The Future of 3D Printing in Heat Treatment: How Normantherm is Leading the Way.

At Normantherm, we specialize in advanced vacuum furnace solutions engineered for precision, efficiency, and long-term reliability.

Our vacuum furnaces are engineered to deliver precise temperature control, superior process stability, and consistent results for advanced heat treatment and brazing applications.

Get In Touch